Australian scientists flag dramatic improvement to next-gen perovskite R&D

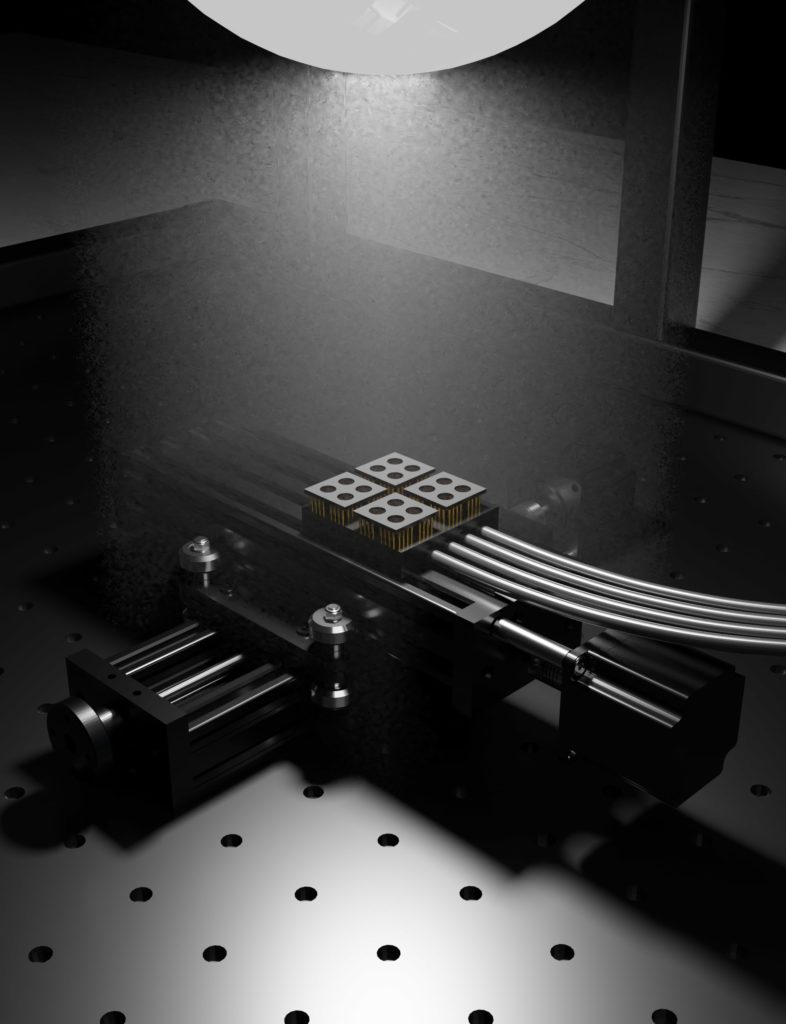

Credit: Adam Surmiak, Xiongfeng Lin

Tests on new designs for next-gen solar cells can now be done in hours instead of days thanks to a new system built by scientists at Australia’s Monash University, incorporating 3D-printed key components.

The machine can analyse 16 sample perovskite-based solar cells simultaneously, in parallel, dramatically speeding up the process.

The invention means that the performance and commercial potential of new compounds can be very rapidly evaluated, significantly speeding up the development process.

Continue reading 3D-printed system speeds up solar cell testing from hours to minutes